Experience our outstanding services and support as well as reliable processes, human resources, and company strategy to deliver exactly what you need.

WATER TREATMENT

Water is a very important medium in a wide range of industries, where it is normally encountered as raw water, process water or as wastewater. This water needs to be treated prior to entering the process to ensure that its quality and properties will support the industrial process as effectively as possible. At least it needs to be ensured that it will cause minimal damage to process equipment. Furthermore, a clear trend today among industries that use large amounts of water, such as steel, food & beverage, etc., is to recycle and reuse water to an increasingly high degree, thereby reducing water consumption as well as pollution – all of which lead to cost reductions. Efficient water reuse can result not only in energy efficiency and decreased environmental impacts but also in significant cost savings.

Water treatment is any process that improves the quality of water to make it appropriate for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment.

Water treatment removes contaminants and undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use, not only for drinking and other daily uses but also for social and economic activities in the areas of production, processing and transportation. For water treatment plant operation like water treatment of boilers and cooling towers, it is an integral operation for many industries, with productivity and product quality hanging in the balance. Scale, corrosion, fouling, microbiological contamination and other water treatment problems can be costly.

WASTE WATER TREATMENT

Waste water treatment aims to remove as much of the suspended solids as possible before the remaining water, called effluent, is discharged back to the environment. As solid material decays, it uses up oxygen, which is needed by the plants and animals living in the water.

Wastewater treatment process does not only produce clean reusable water, but also has the potential to produce various other benefits. It has the potential to reduce a country’s waste production, to produce energy through methane harvesting, and the potential to produce natural fertilizer from the waste collected through the process.

Finally the wastewater needs to be treated so that it can be released into the municipal sewer systems or to the recipient and ultimately back into its source.

Objective

Eagle Star Industrial Sales Corporation supplies the expertise to identify the problems, develop solutions and generate efficient water and waste water treatment programs. We can provide full treatment programs including chemical water treatment using our line of products, water analysis and process control equipment.

HYGIENE AND SANITATION

Appropriate sanitation and hygiene practices are critical elements of an environment conducive to producing safe food. These prerequisite food safety programs are particularly important for minimizing the potential for contamination of food products with pathogenic microorganisms. Effective sanitation and hygiene programs also are essential to producing foods that are free from quality defects such as spoilage microorganisms, filth, hair, insects and other contaminants that may not represent a direct food safety hazard.

Plant management must ensure hygiene and sanitation as the top priority to minimize the chance of recall.

Objective

Eagle Star Industrial Sales Corporation is engaged in hygiene and sanitation programs of most industrial manufacturing company particularly food and beverage industries. Our clients include mostly branches of Coca Cola Philippines. Our product lines for hygiene and sanitation are FDA Certified and safe to use. We provide package for hygiene and sanitation program like supply of sanitation cleaning chemicals, consumable materials and trained technical staffs.

DESCALING OF BOILERS, HEAT EXCHANGERS, CONDENSERS & COOLING TOWERS

The build-up of hard water scale in boilers, heat exchangers, cooling towers and pipework reduces the efficiency of heating equipment. Acid cleaning is the only satisfactory method of removing scale deposits. Acid cleaning involves the circulation of acid at low concentrations around the equipment that requires scale removal.

Hard water scale in boilers, heat exchangers, cooling tower and condensers reduces their efficiency, in a case such as steam boilers, can cause the boiler to be dangerous to operate. Acid cleaning is the only satisfactory method of restoring the heat transfer efficiency by complete removal of the deposits.

Scale, which is mostly calcium and magnesium, acts as an insulator in between the metal surface of a boiler and the water, and will result in an increase in the temperature of the boiler metal. With enough scale, the metal overheats, causing blisters and eventually a ruptured pressure part.

Boilers

Usually, with boilers, the engineering department will fail a boiler if it is considered to be in a dangerous condition, and will not allow the boiler to operate until cleaned satisfactorily. However, if it is required to restore heat transfer efficiency, then the decision to clean can be taken by maintenance personnel.

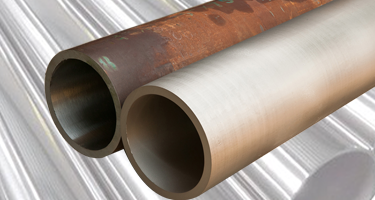

Heat Exchangers

These will suffer from blockage, restricted flow and increased pipe work pressure drop, as well as a reduction in heat transfer efficiency. Acid cleaning should be carried out before the pipe work is blocked completely, otherwise the acid solution cannot be circulated.

Cooling towers

Scale build up in a cooling tower can harbour Legionella bacteria and acid cleaning will be required if scale is present. Any heat exchanger associated with the cooling system may also require an acid clean.

Evaporative Condensers

The tubes of an evaporative condenser are simply a heat exchanger that is cooling refrigeration gases. Not only will there be a reduction in cooling efficiency, but the refrigeration plant will also be inefficient if the gas is not cooled correctly.

DEEP CLEANING / STAINLESS

When clean, stainless steel creates a seamless, timeless look. But, to keep it clean, it requires more work than any other type of appliance material. Stainless steel collects fingerprints, smudges, streaks, and more. Any little contact with the exterior leaves a mark.

Stainless steel can last for years if it is cared for regularly, which is one of the best and biggest benefits of incorporating this style into production process of food and beverage industries.

Objective

We do an intense removal of dirt or smudges that collect on surfaces of stainless and more complex operations for removing free-iron contamination that may have been picked up from the tooling. . We remove filth, slime, acid stains, organic soils, any discoloration on the surface and watermarks on stainless surfaces/tanks, leaving it restored almost like new. We help our client to eliminate costly replacement of stained materials.

PASSIVATION SERVICES

Passivation is a chemical processing service in which metal is treated to inhibit surface corrosion. Passivation is essentially a surface cleaning operation with solutions which has the effect of eliminating surface contamination that may cause discoloration and superficial corrosive attack on service. Typical contamination includes iron from cutting tools and contaminated sandblast materials.

The removal of these residues from stainless steel surfaces promotes the complete formation of the invisible oxide film that gives these alloys their corrosion-resistant properties. Passivation helps extend the life and integrity of products.

Objective

We offer passivation services to insure the maximum corrosion resistance of the austenitic stainless steel and restore or enhance the chromium oxide film on the stainless steel surface when it has been manipulated by surface finishing, welding, grinding, external contamination, etc. that helps to extend the life and integrity of products.

OVERHEAD TANK CLEANING

Regularly cleaning of water tanks not only prevents the outbreak of disease due to pollutants but also keeps at bay common health problems such as cholera, dysentery and gastroenteritis. Apart from the health benefits, regular water tank cleaning is also cost effective and prolongs the tank life.

Objective

We offer a tank cleaning to help our client to save time and money on repairs and replacement of tank, to maintain their tank structure is less prone to being damaged, but also reduces the probability of damage caused by corrosion.

KITCHEN EXHAUST DUCT CLEANING

Kitchen extract systems are coated with grease, oil, and other residues that may ignite and cause fire to spread rapidly throughout the exhaust system. It is vital to keep kitchen exhaust duct clean for a better and safe commercial kitchen to show that you care about the quality of the meal and the health of your customers and employees.

Objective

Eagle Star Industrial Sales Corporation’s Kitchen Exhaust Duct cleaning involves removing grease that has accumulated inside the ducts, hoods, fans and vents of exhaust systems of commercial kitchens. Having clean exhaust system reduces maintenance over time and saves you more money on your power bill and providing a safe and better commercial kitchen for your customers and employees.

AIRCON CLEANING AND MAINTENANCE

Aircon cleaning services using cleaning chemicals is normally recommended for air-conditioning systems or units which have been in use for quite a number of years without maintenance or proper maintenance. Chemical wash removes mouldy growth which gives filthy odour and reduces the efficiency of product drastically. Most beneficial aspect is that it prevents mechanism from breaking down and helps to regulate healthier as well as cleaner air.

Objective

“We offer professional aircon services such as air conditioner cleaning & maintenance, chemical cleaning % air conditioner washing, air conditioner troubleshooting & repair, and other air conditioning unit services. Our segment market includes residential, condominiums, offices, commercial and industrial establishments.”

DISINFECTION SERVICES

Disinfection is the process of eradicating pathogens on the environmental surfaces and other inanimate objects. The use of physical or chemical processes helps to reduce, remove, inactivate, or destroy pathogenic microorganisms. Disinfection procedures are crucial in controlling the spread or transfer of microorganisms between animals, between locations, or to people. The potential for spread or transfer of microorganisms can occur from the direct or indirect contamination of equipment, facilities, vehicles and people.

Many germs and virus are found on the surfaces in your workplace, offices and home. It is important to keep all your work surfaces clean, especially during a pandemic or emerging disease event.

Objective

We offer disinfection services that kill germs on surfaces or objects after cleaning and using our own disinfection chemicals, helping our client to lower the risk of spreading infection.